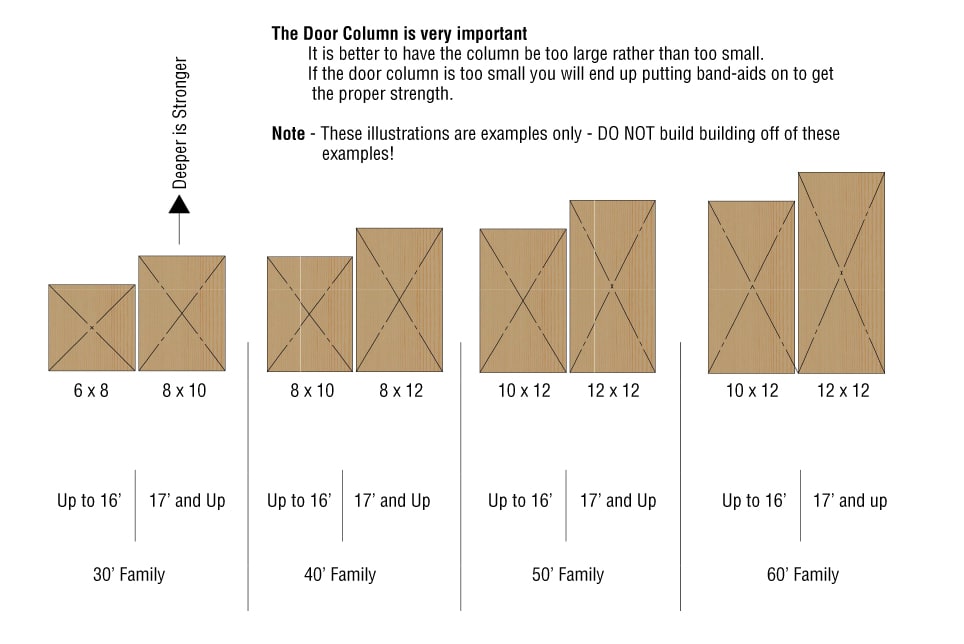

There are a few things to understand about the way your building should be structured when adding a hydraulic door. A common concern is that the hydraulic door puts a lot of stress on the building, which is not untrue. Many wood building engineers have a tendency to get lax with the design of the supports for the hydraulic door as well as the framing and forget that we not only have to support the weight and wind on the door, but also its operation. It is better to overbuild now than have to worry about making costly repairs later.

The hydraulic door is not a billboard; it is not capable of standing independently. All the forces from the hydraulic door opening and from wind loads will get transferred through the door subframing to your building.

Use common sense when designing your building to have a hydraulic door. Don't assume that your hydraulic door can be left open in windy conditions just because your building can handle the weight of the hydraulic door. And be sure to refer to the Schweiss hydraulic door specification sheets that come with each hydraulic door to help you understand the forces.

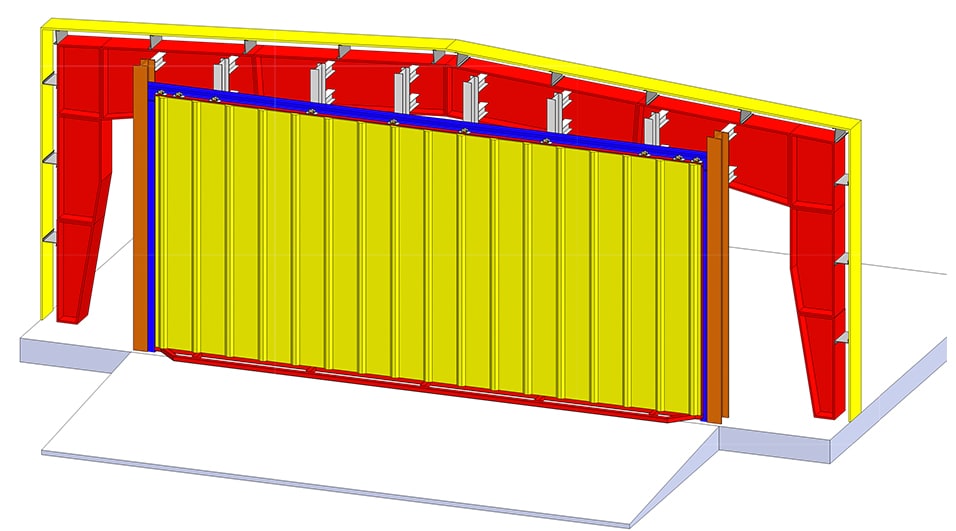

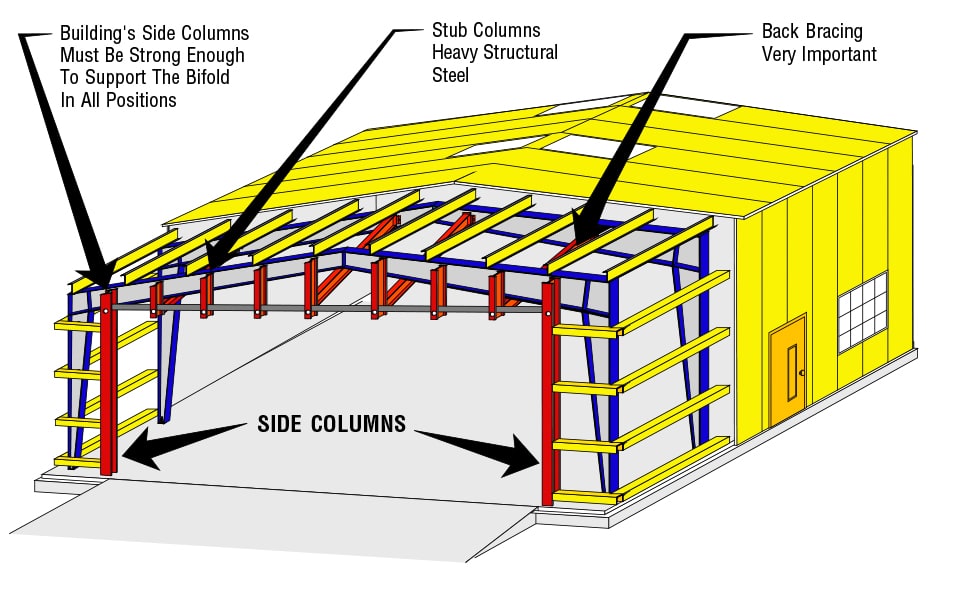

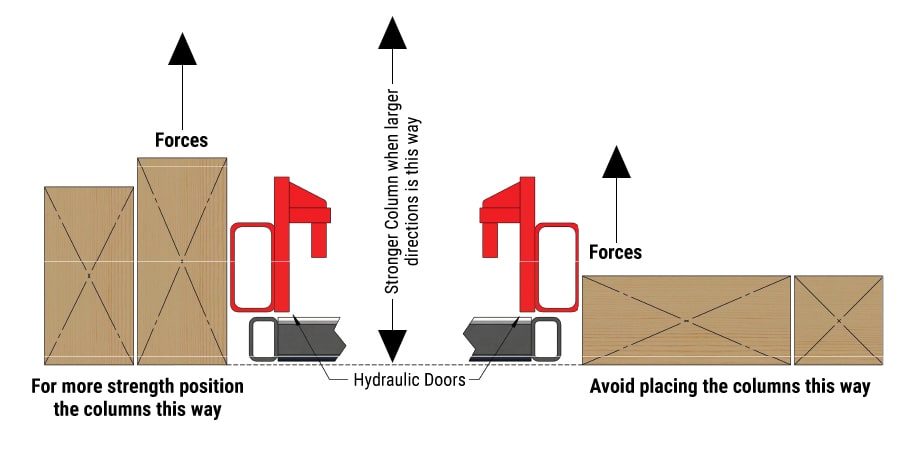

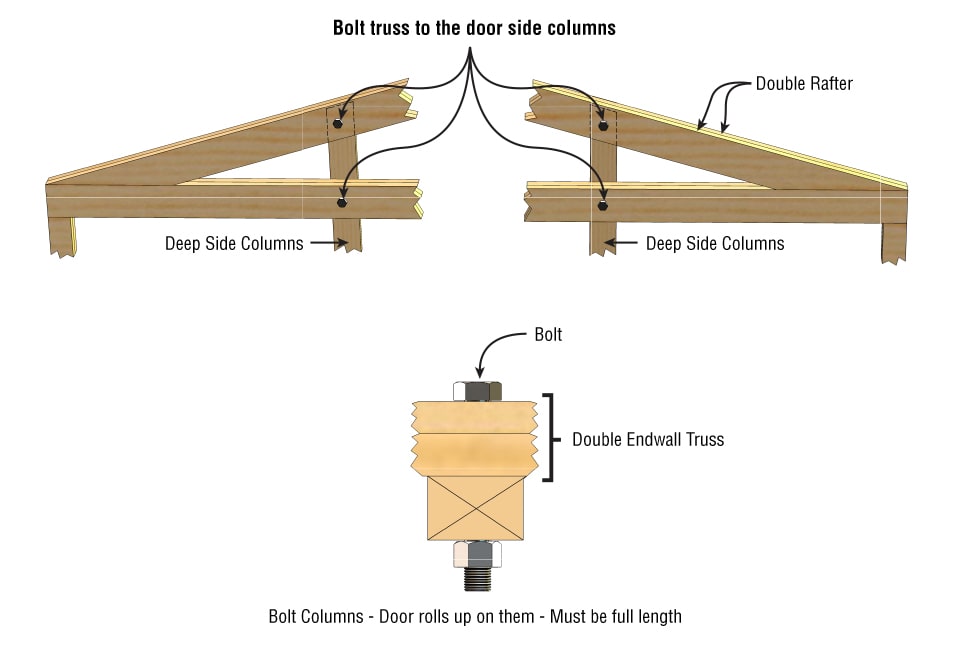

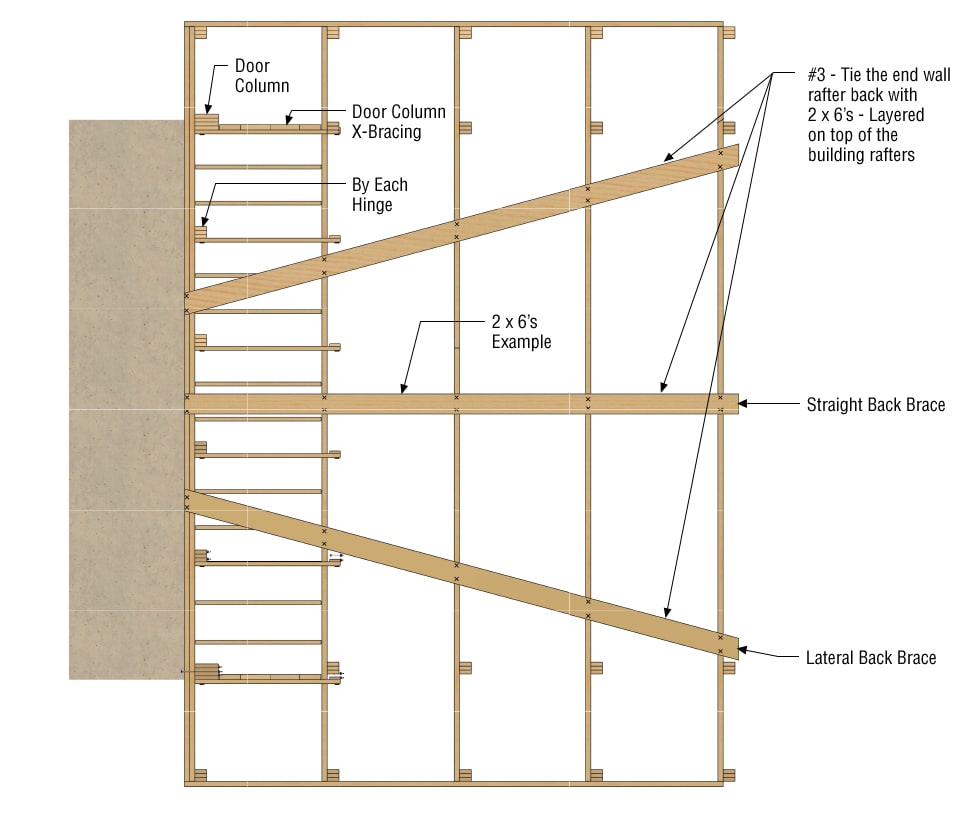

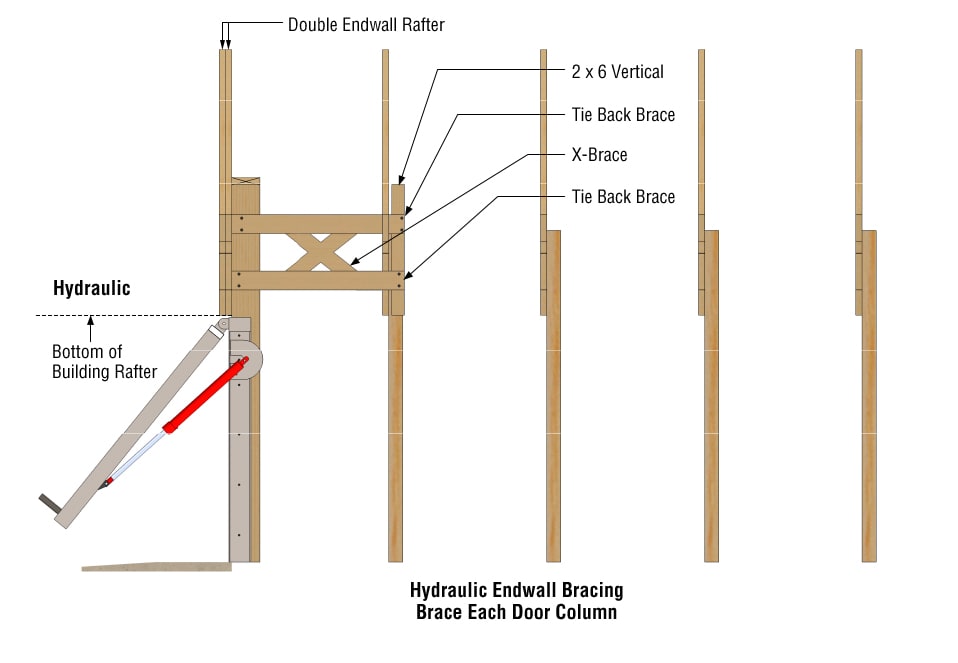

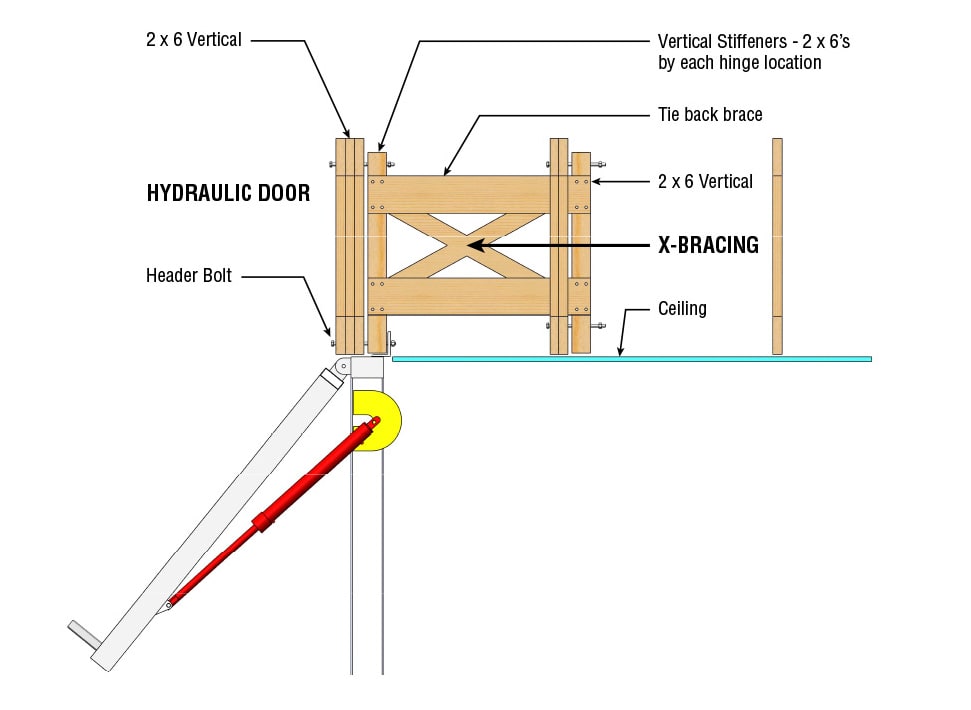

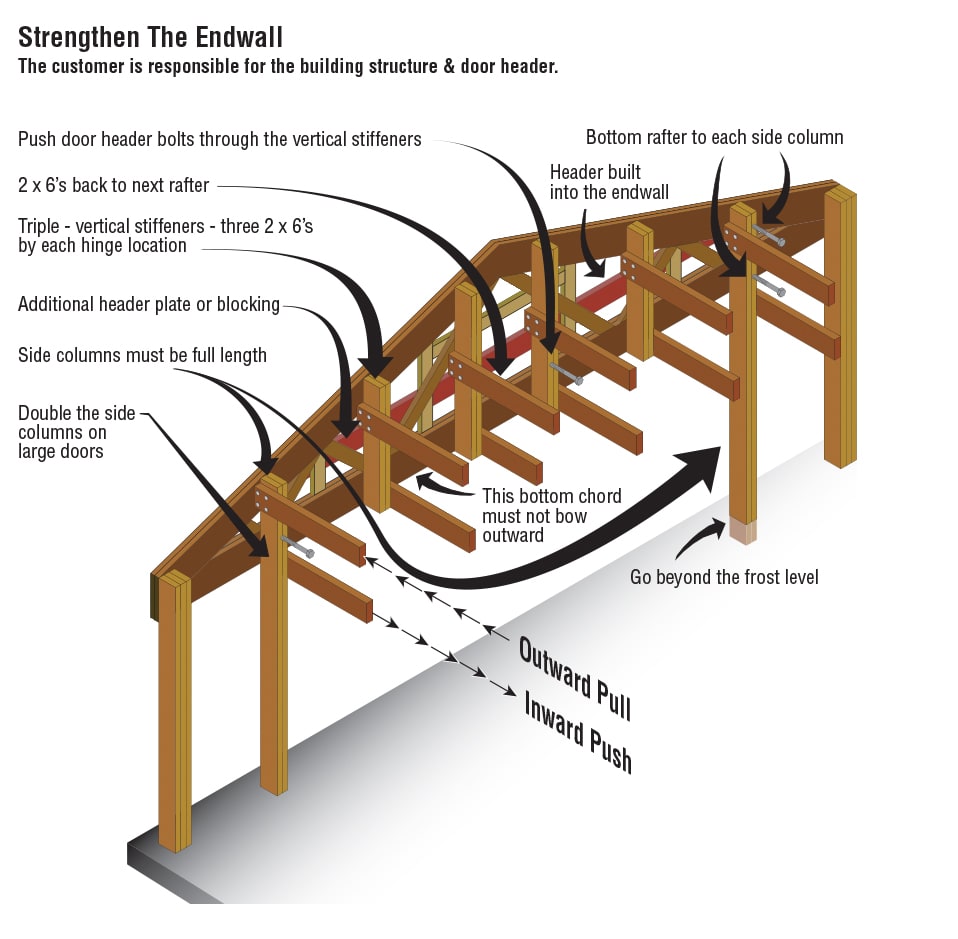

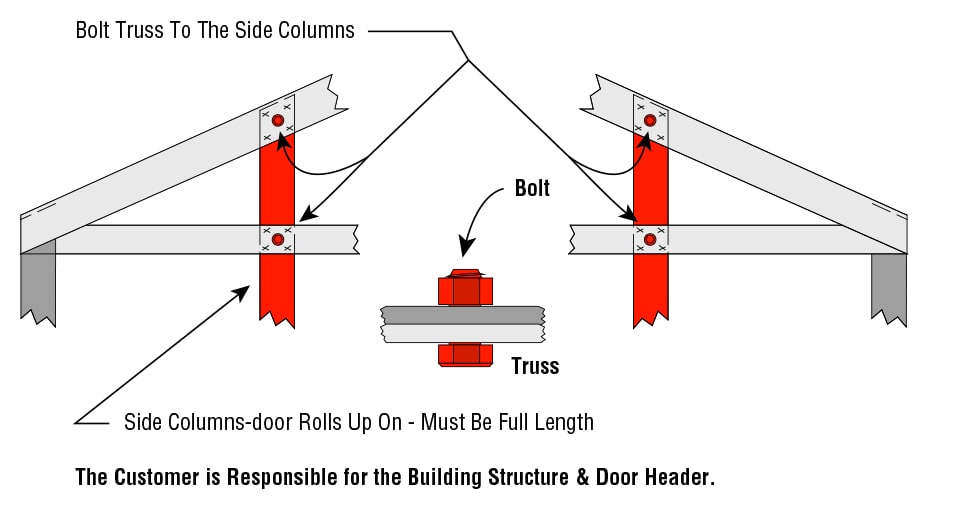

Hydraulic doors come with two powerful cylinders that are pre-mounted to a vertical subframe with one cylinder on each side of the hydraulic door frame. The cylinders exert strong rotating forces to the hydraulic door side columns as the hydraulic door operates. It’s important to limit the rotation of the hydraulic door side columns when the hydraulic door is open, as well as when it is opening and closing.

The building could be considered to be "acceptably designed" if the designer is told the correct loads that are going to be put on the building and they have designed the building to withstand these loads.

Existing buildings can be a bigger problem. They may not have been designed for the intentions you have for it, or the original designer or building company may not be willing to help. It is important to either have a qualified engineer or the original designer design the modification using the correct loads and eccentricity information. All of the "recommendations" that Schweiss has on their spec sheets are recommendations that go a long way toward making the building appropriately.

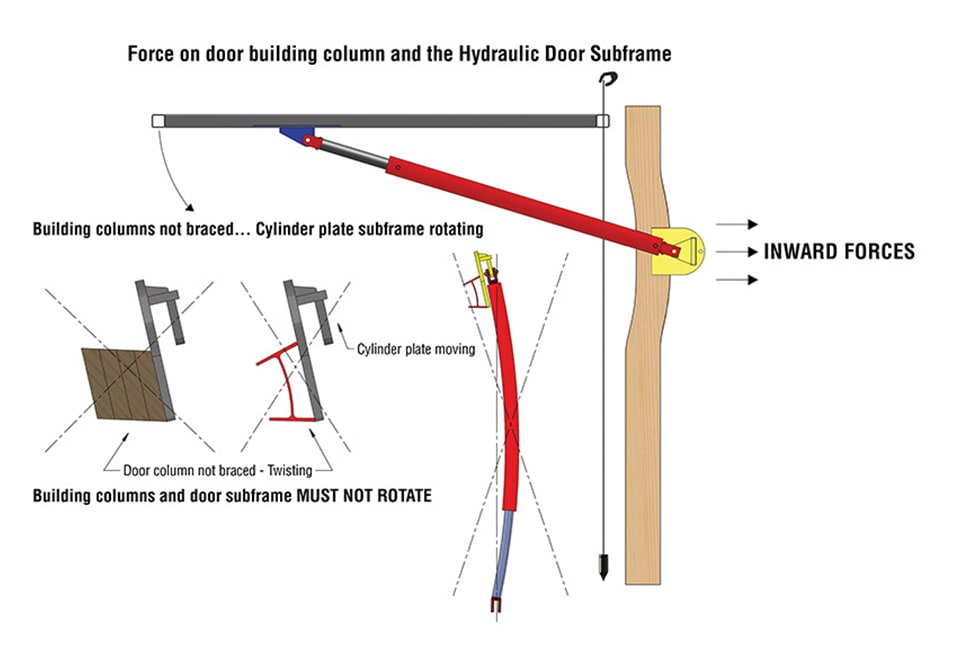

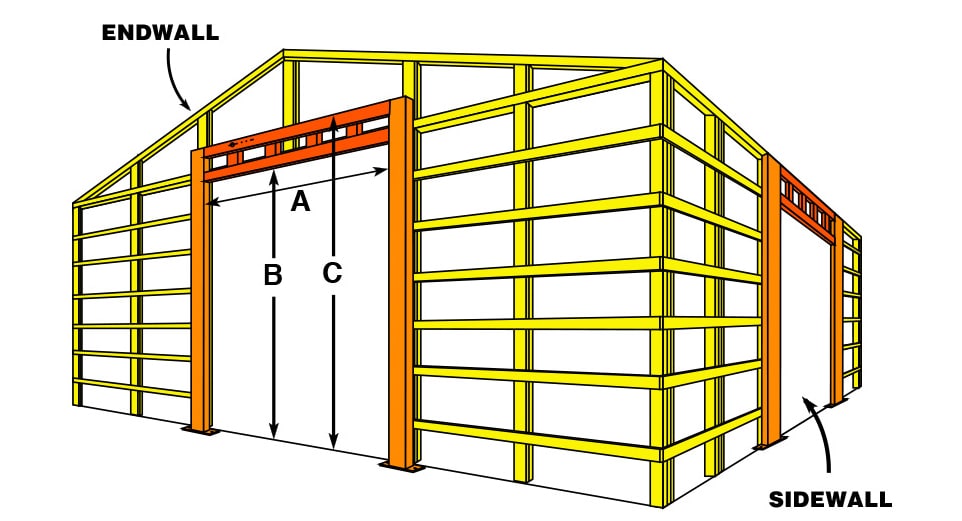

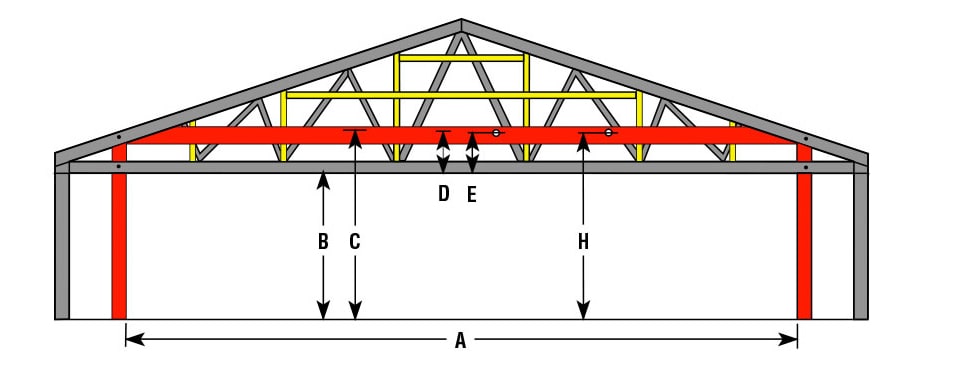

The hydraulic cylinders exert rotating force to the building door side columns as the door is being operated... See Below

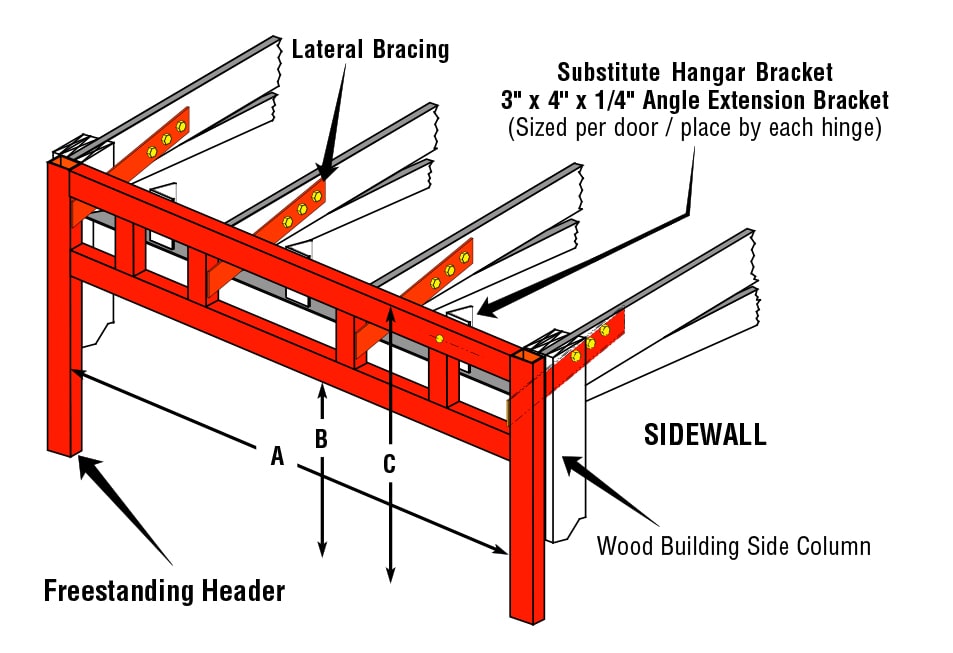

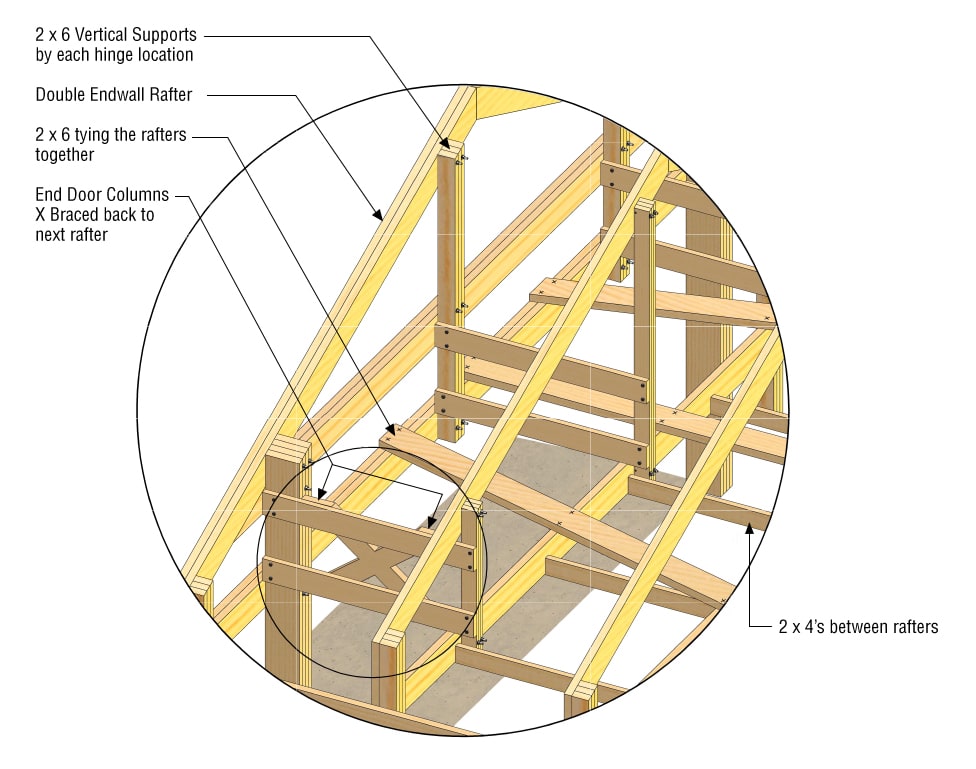

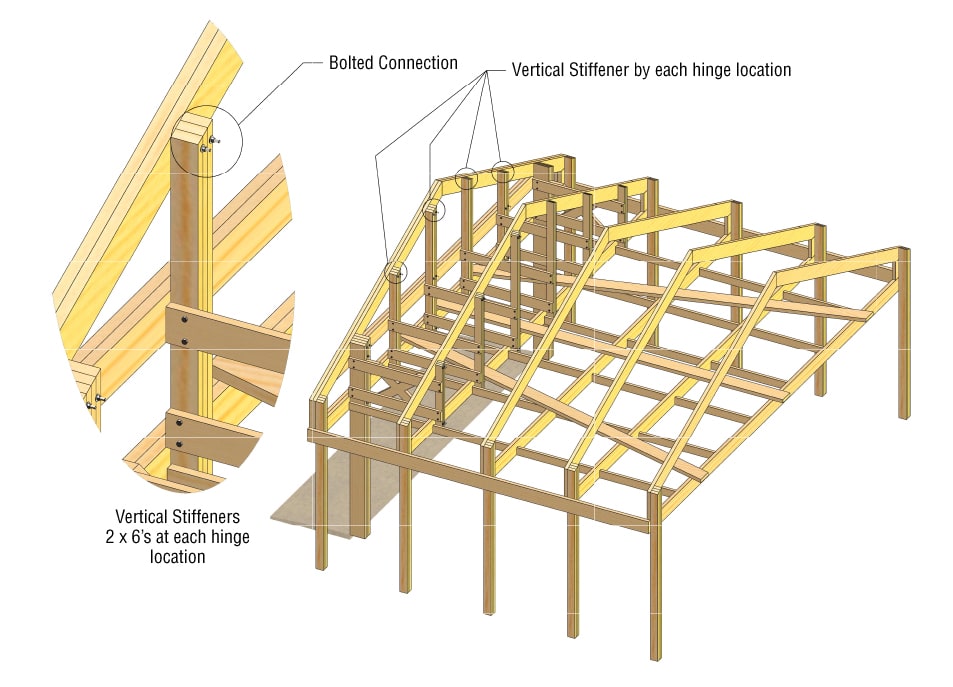

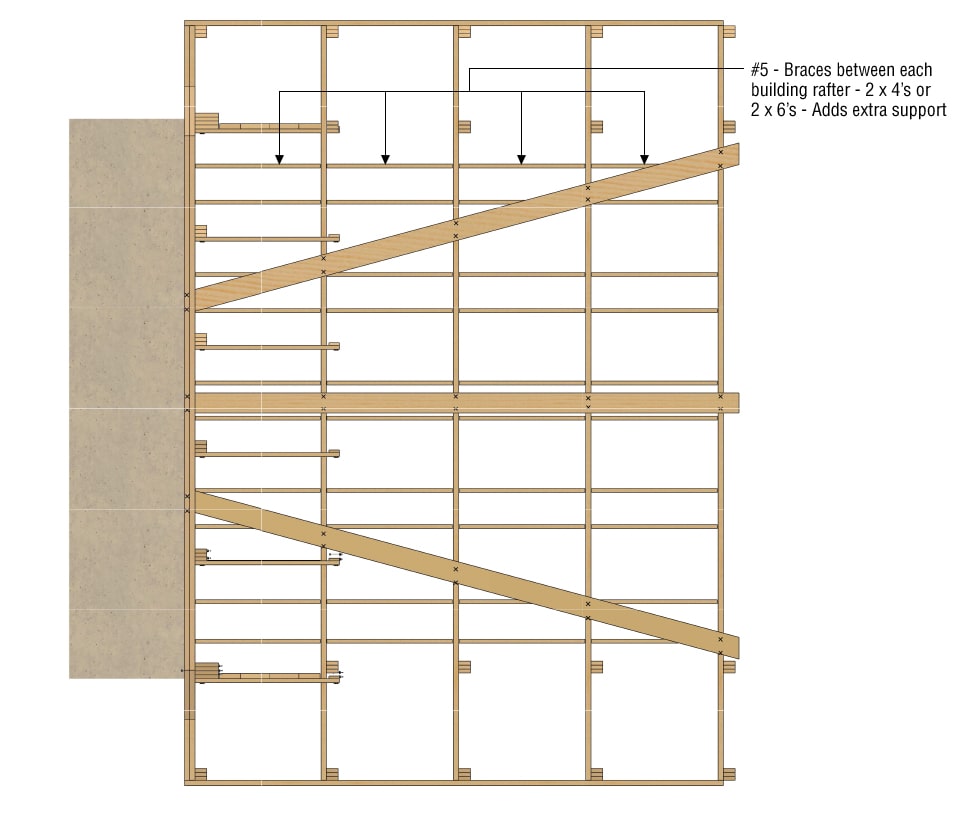

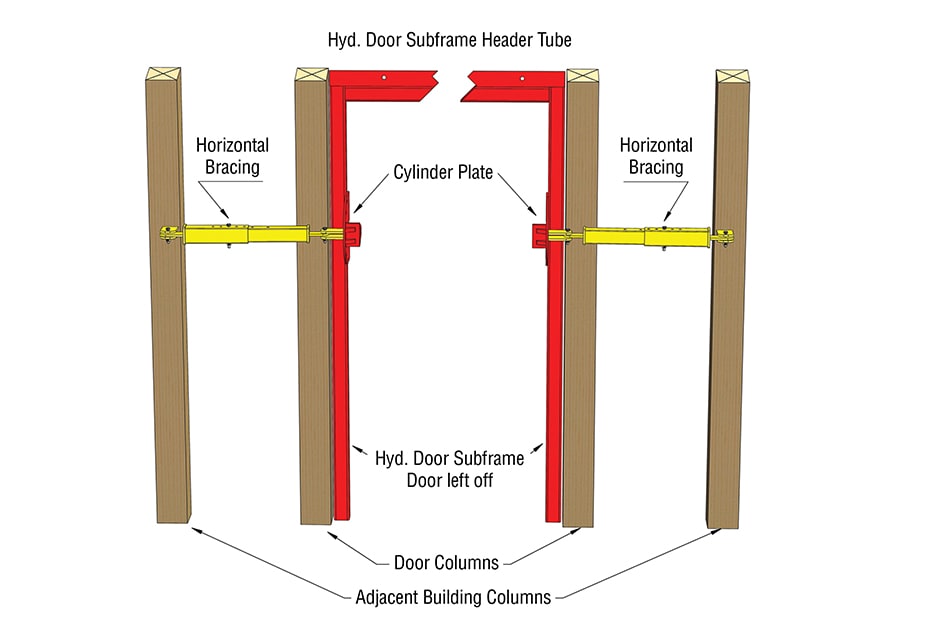

Horizontal Bracing...increase the torsional stiffness of the door columns

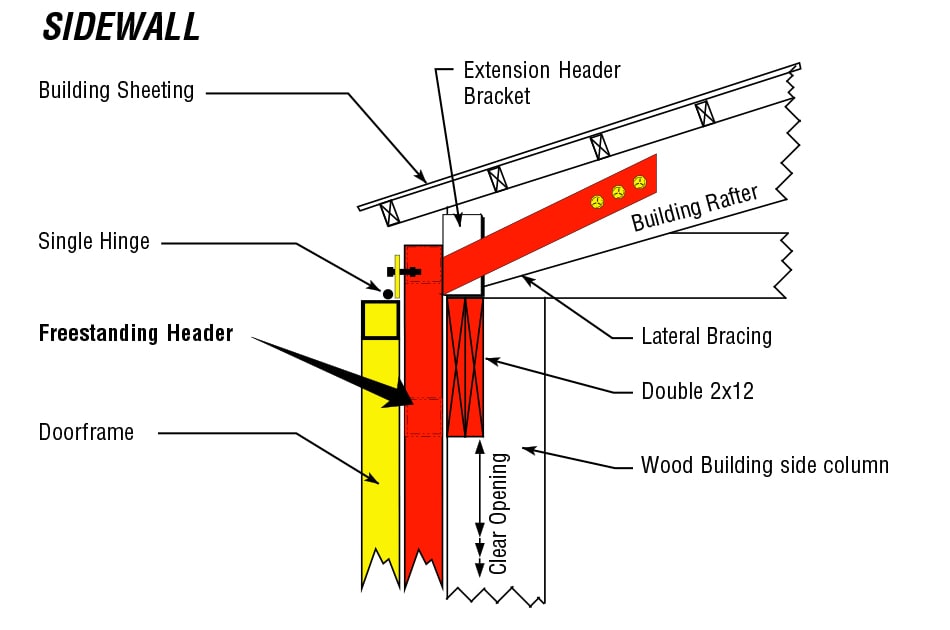

The subframe that the hydraulic cylinders attach to mount to the building door side columns. The hydraulic cylinders exert strong rotating forces to the building door side columns as the door is being operated. It is important to limit the rotation of the door side columns. To aid in limiting this rotation, horizontal braces are strongly recommended at the point on the door column where the cylinder attaches.

Horizontal bracing is used to stop the doors vertical subframe and cylinder bracket and buildings door side column from twisting. To help resist the torsional forces in the door side columns, use horizontal bracing to the next adjacent building column in the plane of the door. These horizontal braces help resist the torsional load in the door side columns.

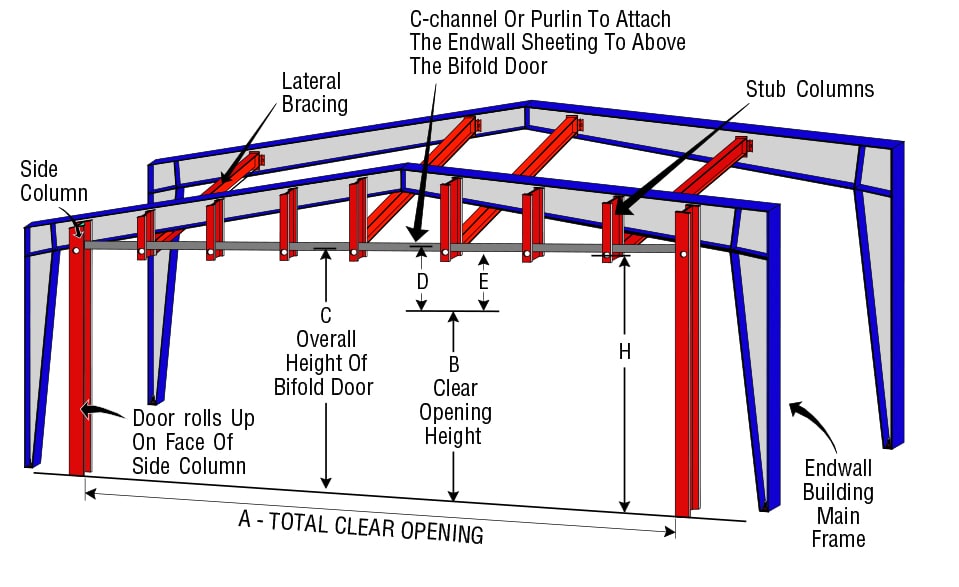

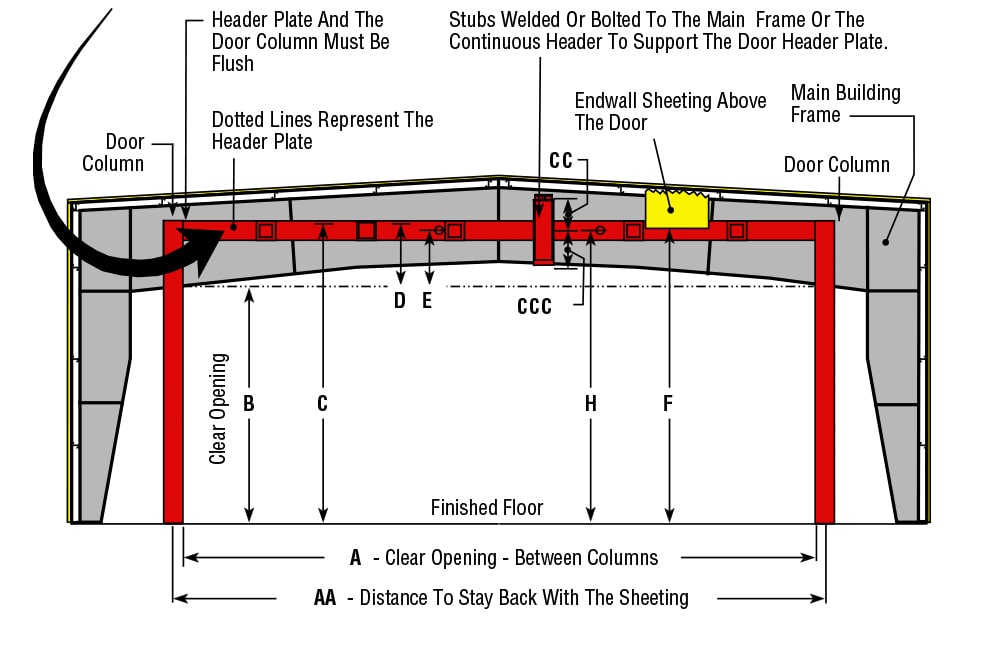

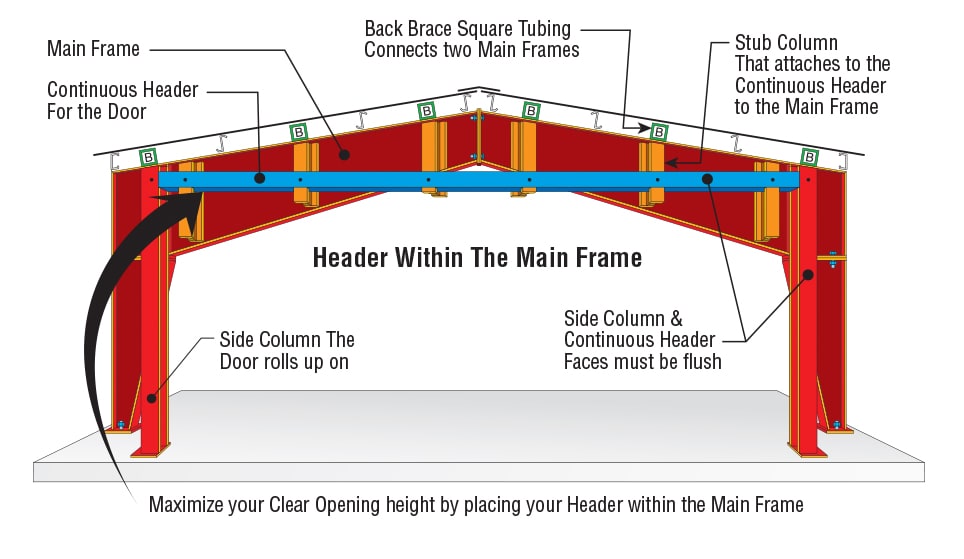

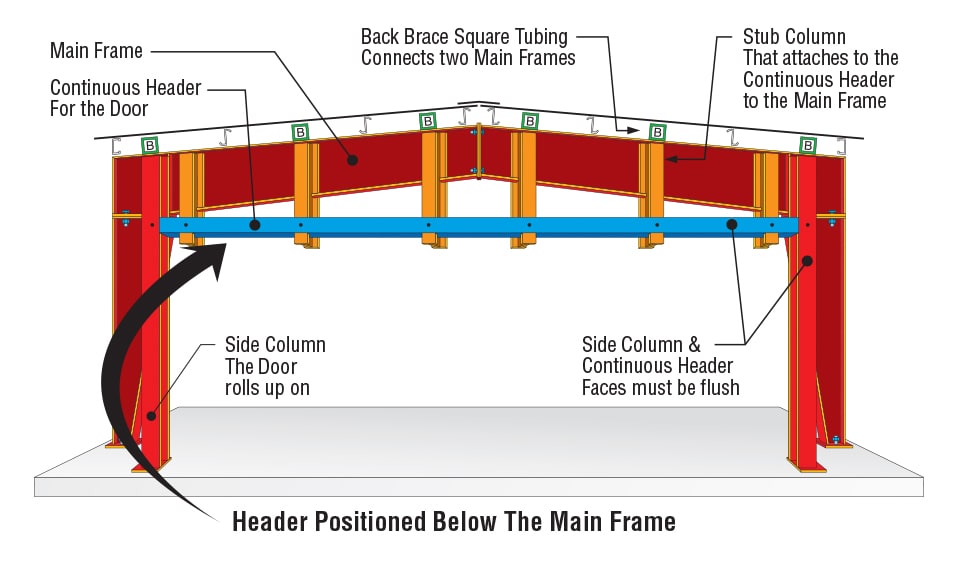

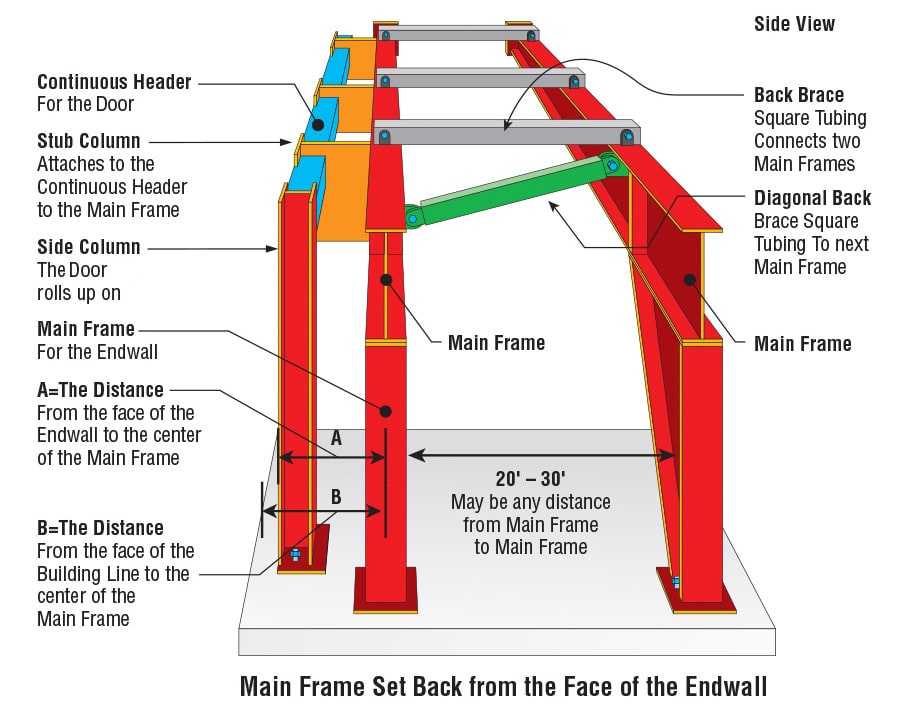

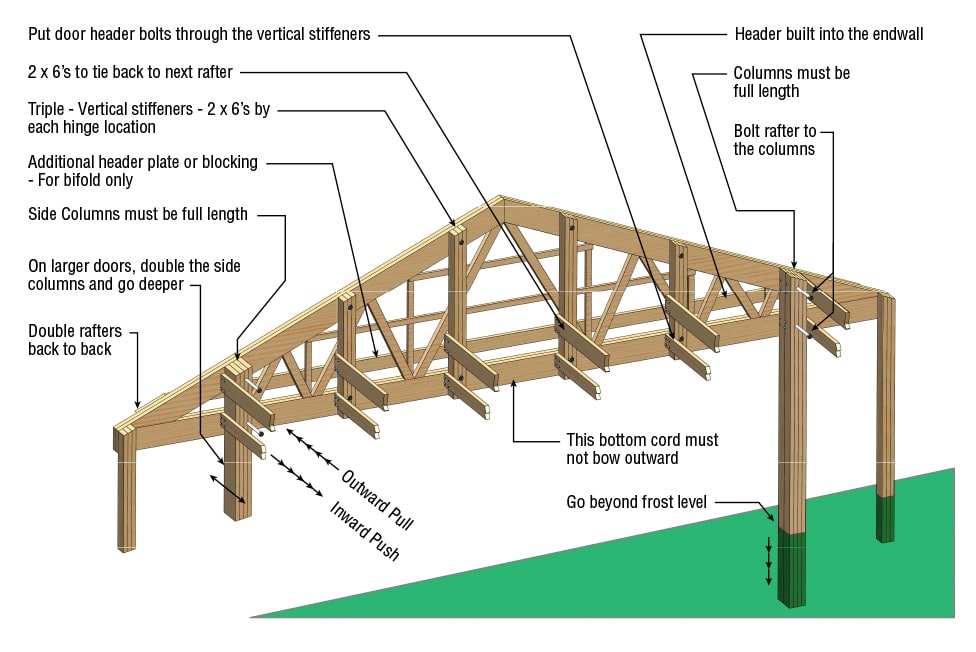

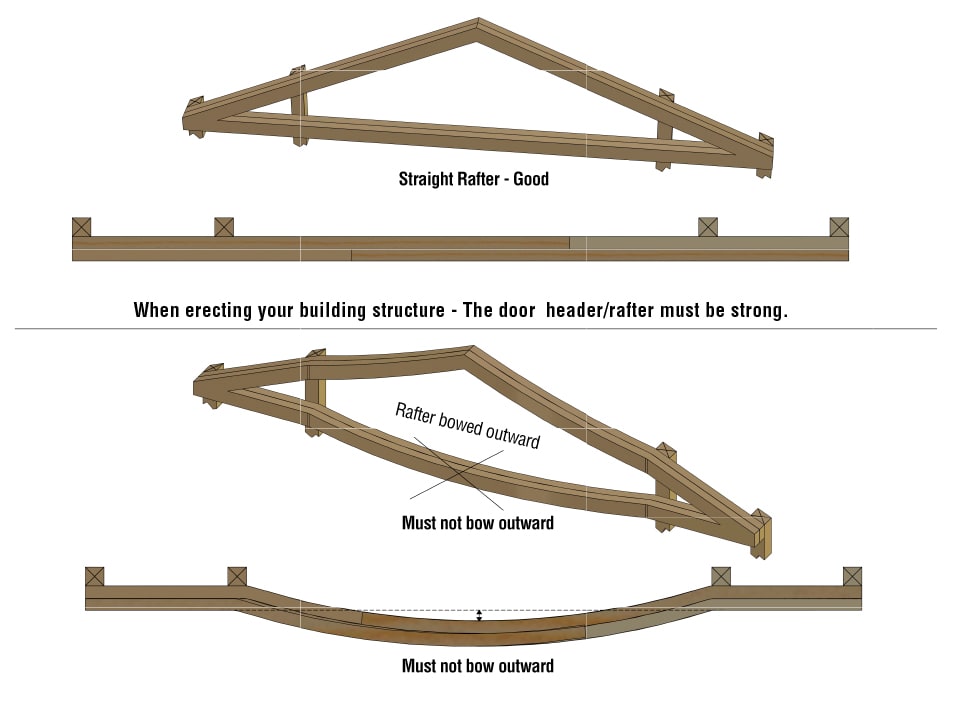

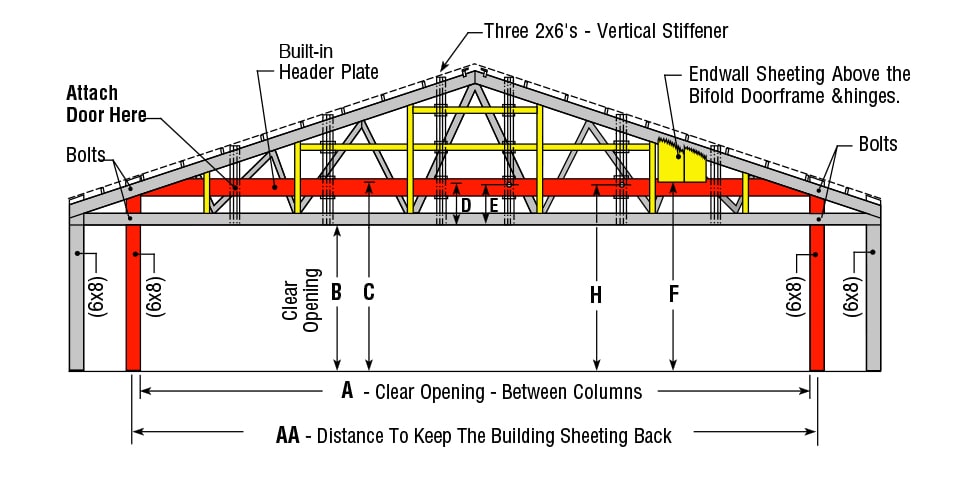

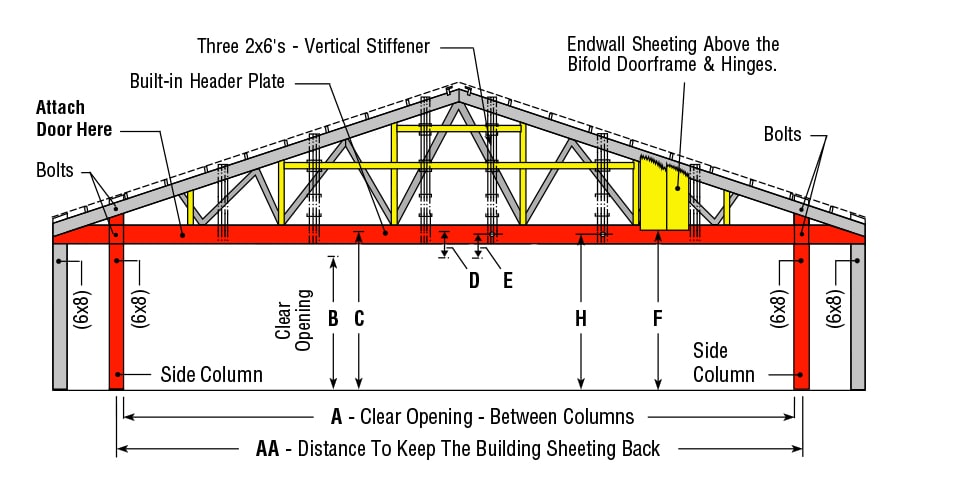

Shows where a header is installed in an endwall of a building. The header is positioned up above the bottom of the rafter so you won’t lose any headroom!

Open Endwall Rafters - Header Placements

We work with old or new buildings to make your bifold door work.

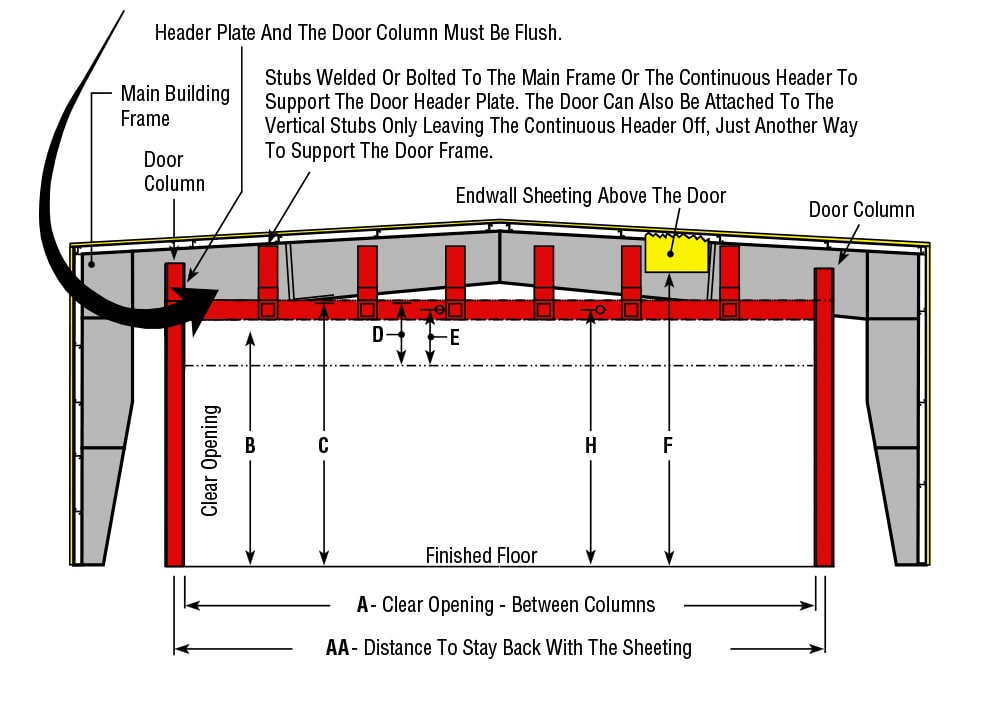

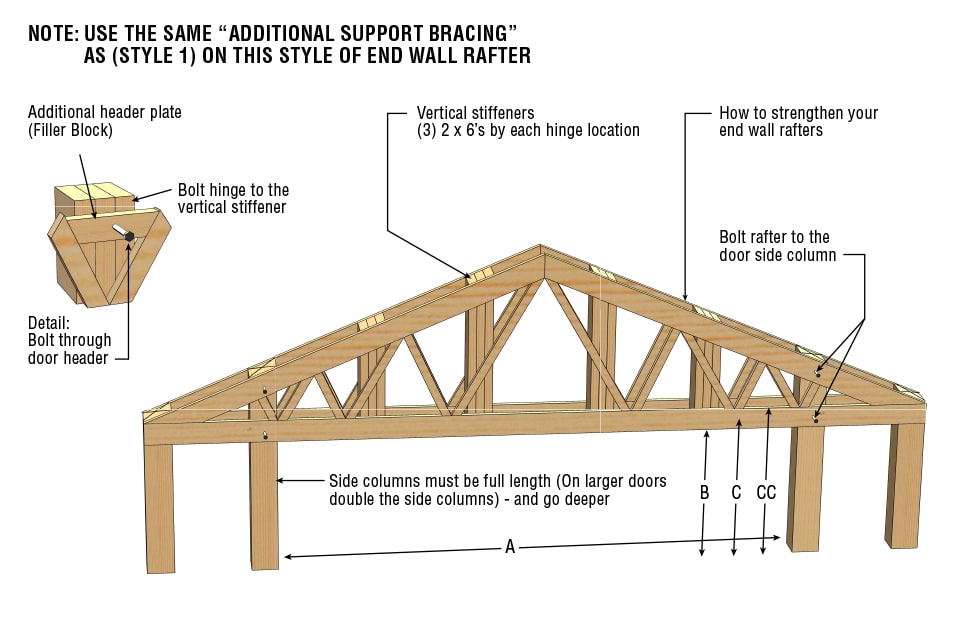

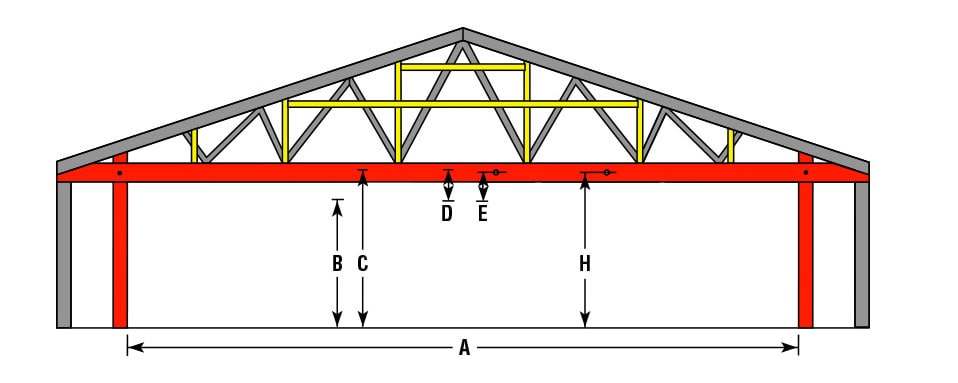

Shows where a header is, using the bottom chord in an endwall of a building.

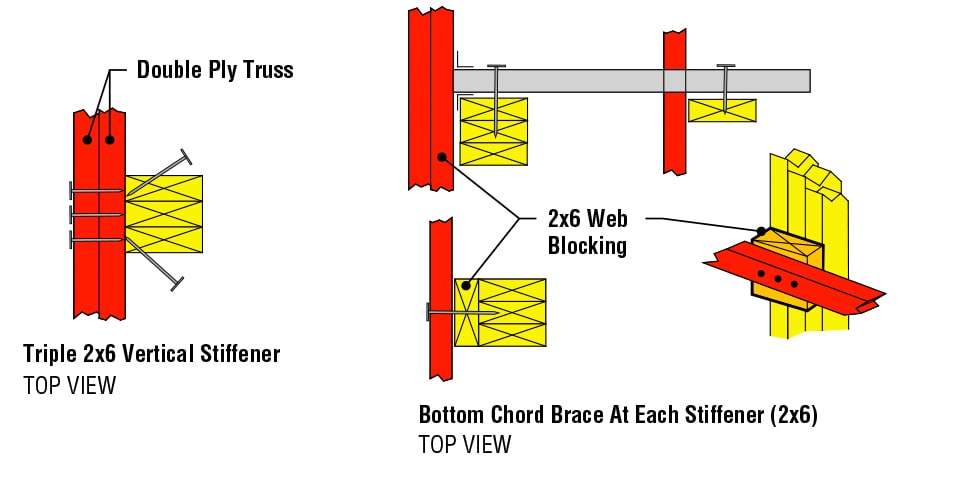

The engineered rafters can be doubled up to sufficient support.

On double endwall trusses where the outside ply is a "Gable Type" truss and the inside is an "Intermediate Truss", there will be locations where there is a 1:50" space between the vertical stiffener and the horizontal members of the gable truss.