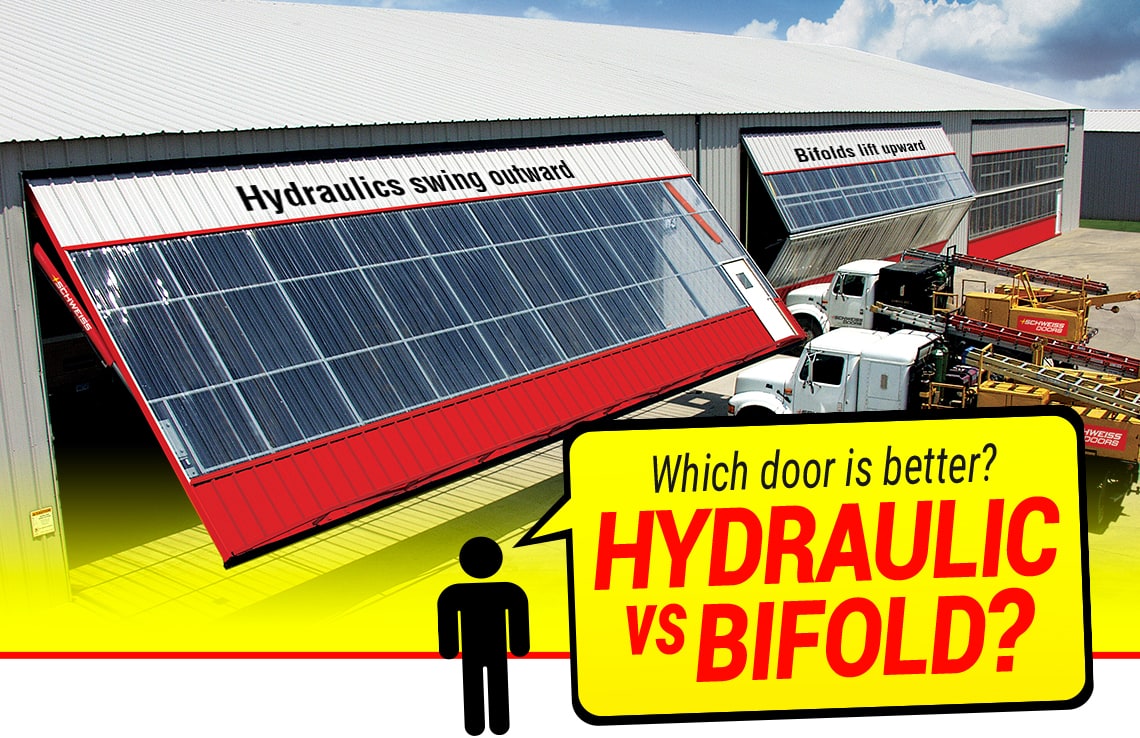

"The choice is yours. Each door offers something different. Each has specific advantages. Tell us your situation

so we can better advise you. The bottom line, its the customers choice. Only Schweiss Doors gives you that

advantage. Schweiss Doors already has a long history in the door world. We are the first choice for thousands of

customers and our Hydraulic Doors are creating great interest. With either door, you get Schweiss Quality. Talk

with us first and we can make your decision easier... Hydraulic or Bifold!"

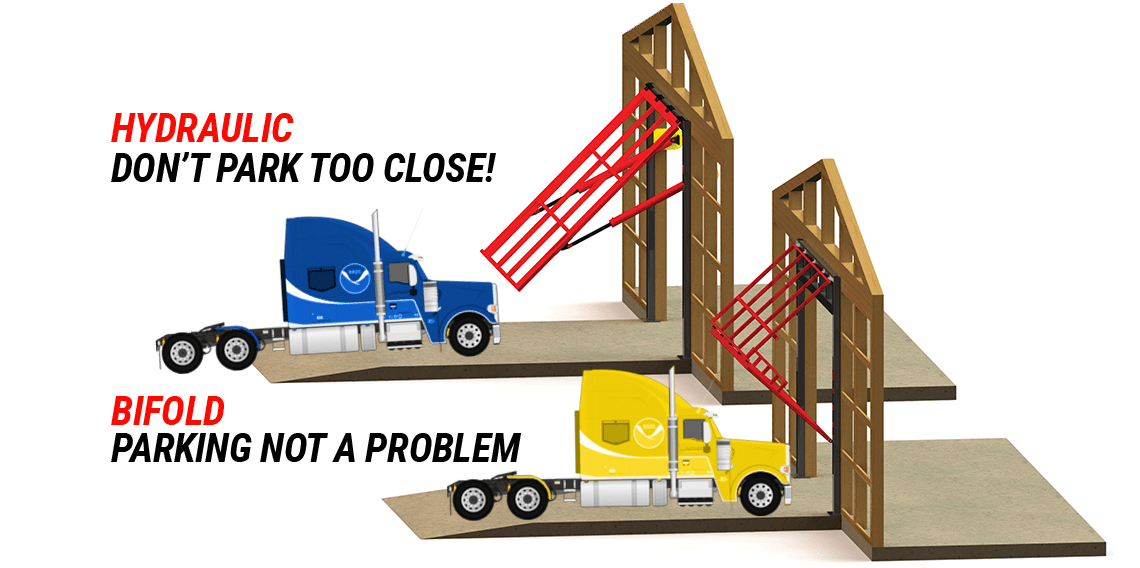

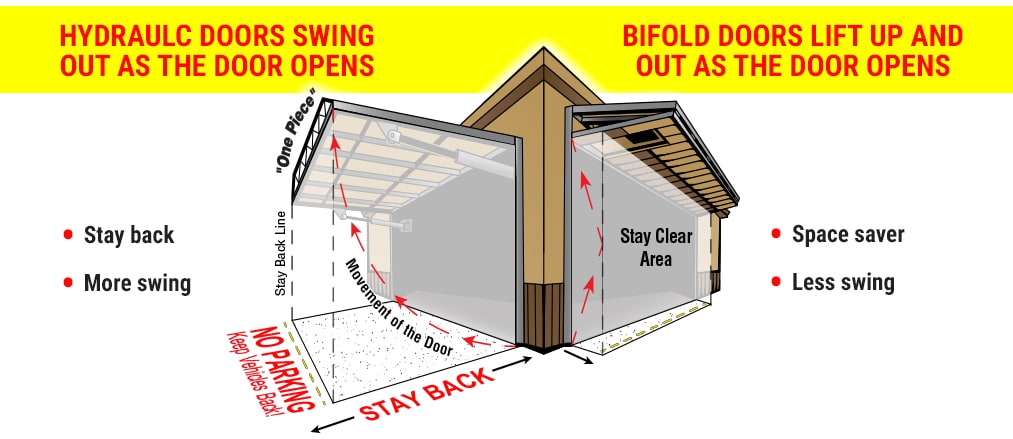

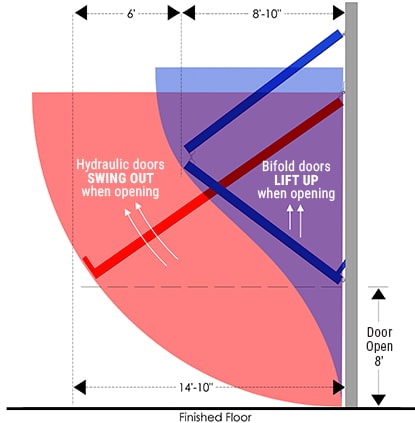

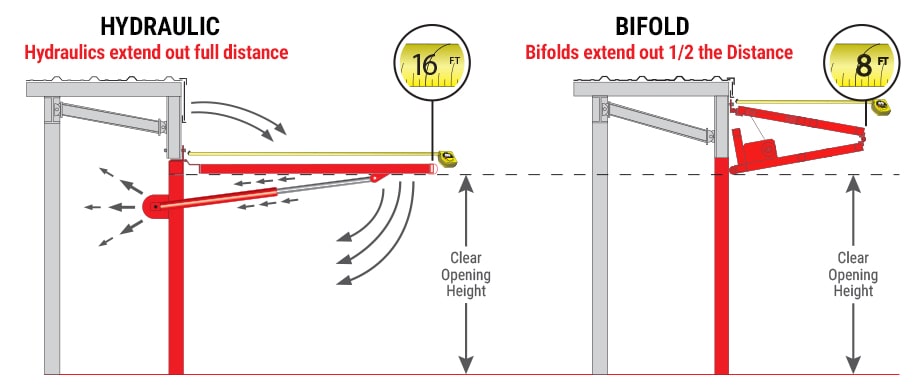

The One-Piece® hydraulic door acts as a large moving wall that swings outward when opening, requiring extra

space as the door travels outward to the open position.

To avoid possible damage to equipment, vehicles and airplanes, clearly label the doorway or ramp area

"No Parking Area". By clearly marking the "No Parking Area" there will be minimal loss of valuable parking

space in front of your hangar/fly-in home/shop/warehouse/storage building.

At airports with hangars located on each side of the taxiway, keep the

door open or closed (not half open) to avoid damaging wings as planes

taxi by the front of your hangar door.

Schweiss recommends that all One-Piece® hydraulic doors have

windows in the door frames. Windows will make any obstructions

in front of the door visible to the operator before opening the door.

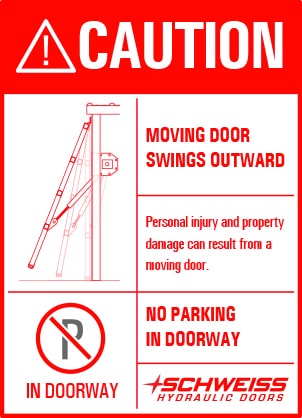

When operating the One-Piece® hydraulic door, you must clearly

warn people. The door swings outward when moving. No parking

in the doorway. Personal injury and property damage can result

from a moving door. WARNING: Schweiss does not recommend

using the space under the door as an extended work area or for

parking your expensive equipment or airplane. Your door is the

largest piece of moving equipment on your building and can be

dangerous. Keep the doorway clear.

Important to Install a window to view the

door travel area

Door swing outward when opening. The doors need extra room to travel when opening.

You must keep the doorway clear of people, vehicles and objects

Caution! No parking on the Ramp or Driveway!

Parking in front of

your door video

SEE THE DIFFERENCE!

Bifold doors have a huge advantage when opening. They start by raising upward, not out ward. They requiring less operating space in the front of your building. The area in front of your large door opening is very valuable space. The two piece bifold allows more usable space in front of your door opening. Bifold doors are a real space saver.

The fact that bifold doors fold in half instead of just swinging out, allows for more open ramp/ vehicle space in front of the hangar. It also allows the full use of the width of the hangar, making the entire end wall a door.

A hydraulic door is ideal in situations where

maximum clear opening must be maintained.

The hydraulic door swings out and away from

the building

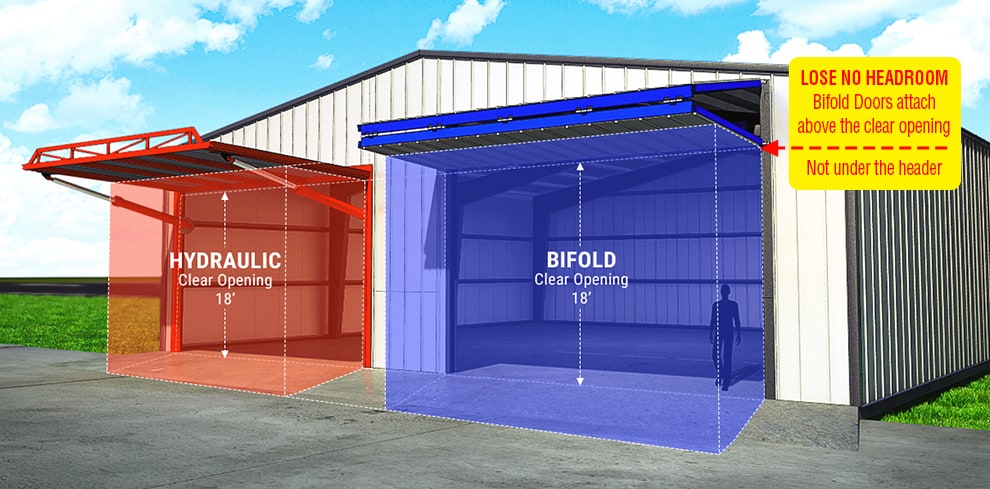

There is no loss of headroom.

There is no headroom lost inside the building.

Bifolds doors mount up and above the clear opening on

the outside of the building structure.

The bifold doors lifts up and out from the building

No need to make the building taller

There is also no headroom lost inside the building.

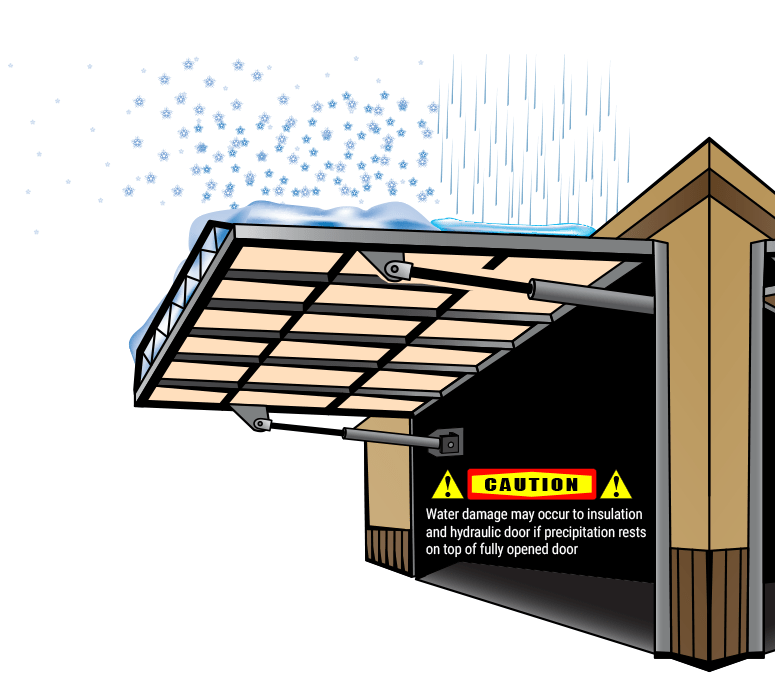

The One-Piece® hydraulic door will be at

90° from the building when fully open.

External trusses are standard on hydraulic

doors. Optional Internal Trusses are available.

One-Piece® doors should have a slight

downward slope when open to direct

moisture and water off the door sheeting.

This prevents moisture and water from

seeping under the door sheeting and ruining

the interior door insulation.

One easy way to get slope on your hydraulic doors is to open the door

to allow your vehicle/machinery in, then lower the door to create a slight

slope for moisture to run off.

CAUTION: Remember to open the door again when moving

your vehicle/machinery in or out of the building.

Request a taller door frame that allows you to open your door to the full clearance while still

having a slight slope to the door in the full open position allowing proper drainage.

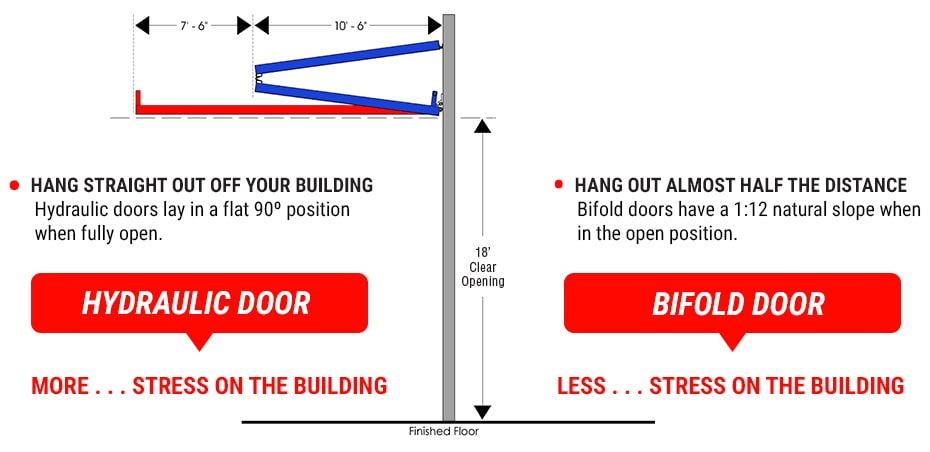

Bifold doors have a 1:12 natural slope

when in the open position.

The sheeting on bifold doors are flashed

to allow water to easily drain off the door.

Water and snow run off in any position!

Internal trusses are Standard.

No external truss required on bifolds

Hydraulic Doors swing outwards when opening.

Hydraulic doors require more/greater space in

front of the doorway for the door to travel outward.

The fact that bifold doors fold in half instead of

just swinging out, allows for more open ramp/

vehicle space in front of the hangar. It also allows

the full use of the width of the hangar, making

the entire end wall a door.

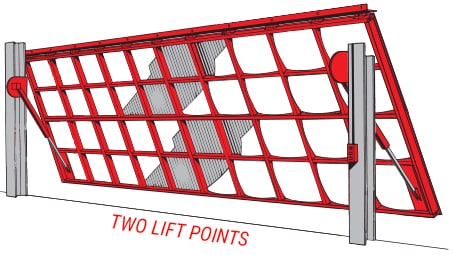

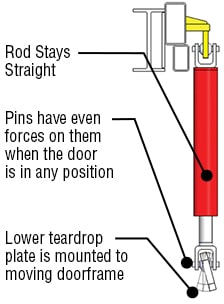

Two lift points

Hydraulic Cylinder

on each end of the

door frame

Two Large hydraulic

cylinders with

spherical bearings

Powerful Hydraulic

Power Unit

Soft shift valves located

on the hydraulic pump

allow Schweiss Hydraulic

Doors to open and close

smoothly preventing any

jerky motion when

operating your hydraulic

door. Schweiss doors are built

with safety in mind!

Schweiss hydraulic doors have built in safety

features.

Like a Hose breaking

Like a Hydraulic line breaking

Like a Fitting failure

Large hydraulic overhead doors must STOP ! ! !

If a hydraulic hose should ever break . . . Schweiss Doors includes velocity fuses that lock up the cylinders that STOPS The Door

If there is a failure of a hydraulic component on a large overhead door, It needs to...

Restrictors / ORIFICE . . .

Have been used by some manufacturers as a safety feature

They may be setting you up for slow motion

disaster, Your worst nightmare!

There's nothing safe about a door slowly, gently

coming down on top of a plane or vehice at a

"controlled rate of speed."

Does your door use restrictors/orifice? Hope not.

Phrases like these are being used to describe the safety of a door.

Gently coming all the way down...

Coasting down...

Controlled rate of decent...

Preventing the door from slamming down...

If the door WON'T STOP it can be

your worst nightmare!

When Purchasing a door find out if your getting

restrictors /orifice . . .

Ask yourself . . . How safe can that be?

No safety built in

Door will come all the way down if theres a failure, no matter what.

No way of stopping the door from coming all the way down

Slow motion disaster

Your worst nightmare

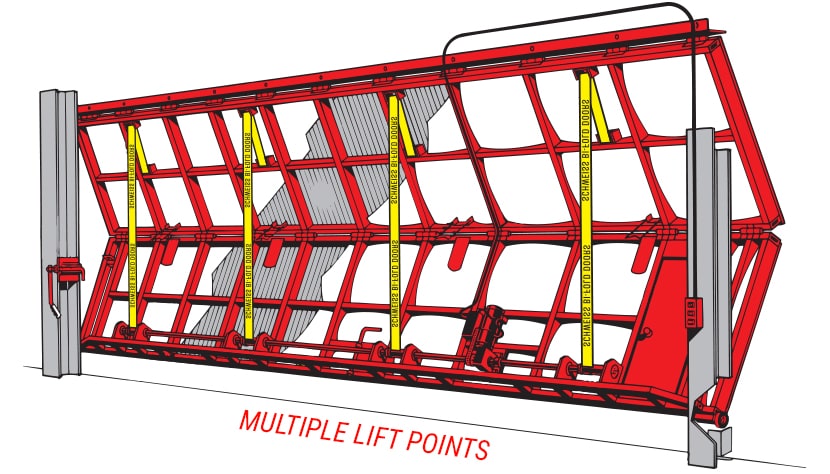

MULTIPLE LIFT-STRAPS RATED FOR 29,000 lbs.

Wider the door the more lift straps that are used.

More lift points evenly distributes the weight of the door.

More lift points increases the doors safety factor.

Motor - GearBox - Electric Brake.

Jackshaft Assembly - Dual Chain & Sprockets.

Hydraulic doors and subframes attach to the

building structure and exert considerable

horizontal and vertical loads to it.

The building must be prepared to support the

forces of your door in all positions.

The longer or further a door frame sticks out

from the building at a 90°, the more torque and

stresses it adds to the building structure and

header.

Hydraulic doors swing out when opening and

cantilever out from your building, pulling away

from the building structure at the hinge line and

exerting additional forces on building header.

Bifold doors fold in half when opening, putting less

stress on the building structure

Bifold doors fold in half when opening and create

a slight slope to allow water to run off.

Bifold door frames attach to the building structure,

exerting forces and vertical loads to the building

structure.

The building must be prepared to support the

forces of your bifold door in all positions.

All doors attach to the building and exert forces onto your building structure.

A one piece hydraulic doors has more surface area protruding 90 degrees off the end of your

building structure

Adding windy conditions to a door in the full open position will cause it to act like an airplane wing

or a parachute, carrying the powerful wind forces back into the building structure.

No matter what size door you have, all the weight and forces are transferred back to your building.

DOOR Truss's can be placed on the exterior of the door or on the interior . . . Customer's choice

An external truss is located on the outside of the One-Piece® hydraulic door frame three inches off the

floor/ground level. The external truss is pre-built to provide added strength and rigidity. Very important in

high-wind conditions. Hydraulic doors are manufactured with a support truss to provide strength and proper

wind loading to the door. It also minimizes the door sagging in the open position.

Custom painted external truss - to match your building

Custom enclosed & flash the external truss give it a neat appearance.

Custom designed trusses to match the look of your building structure.

Raised external truss... keep people/equipment/snow away from bottom truss

"No Truss" on smaller size doors. The "No Truss" look gains valuable headroom and gives

you a clean look both outside and inside the door frame.

Bifold doors are manufactured with an internal truss for support to provide strength and proper wind loading

on the door. Bifold doors come standard with an interior truss that mounts to the inside of the door frame.

Nice clean look outside the door.

Located on the inside of the door frame.

Located out of the weather elements, protected.

No lost headroom.

Internal truss allows you to match your door covering to the building structure's.

It will appear as one continuous wall - with the look of your choice!

Up and out of the way of people walking by or in the area.

Snow plows won't run into it.

Won't collect debris or snow.

Provides extra strength to the door frame.

Allows proper drainage of the door in the open position without a truss to get in the way.

Internal trusses are available on your hydraulic door, but you sacrifice headroom space!

Advantages of an interior steel truss is it will not be exposed to the weather elements.

No place for the leaves, debris or snow to collect or for the snowplow to hit!

When you go with an internal truss you lose headroom unless you mount your door higher.

Located at the center of the door.

Will not collect snow when the door is in the opened or closed position.

When extra strength is needed, Schweiss also offers an external truss.

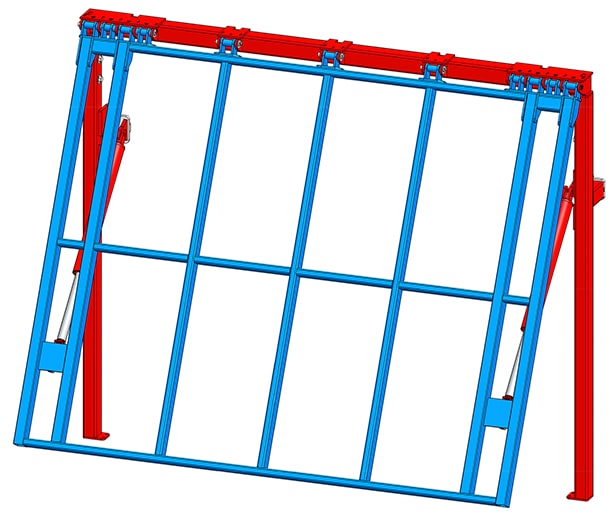

Hydraulic door comes pre-assembled, pre-welded and delivered pre-hung within their own subframe for easy

installation, giving the buyer or builder tremendous flexibility as well as saving time and money!

Double push tube door frame comes pre-assembled, pre-welded and pre-hung to its own subframe

header Tube.

Schweiss vertical door members are stronger and are spaced closer than other's for more strength.

Schweiss does not allow wood on any of it's door frames. Safer!

Provides added support for the door and the building structure.

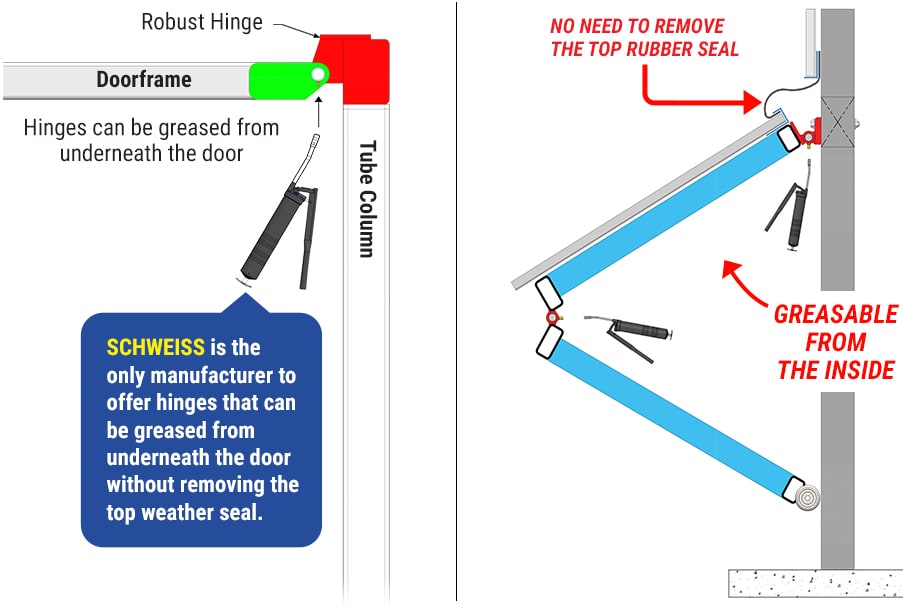

Heavy-duty greasable hinges are pre-located, pre-welded and pre-hung to the subframe header tube.

Mounts to the building structure with heavy-duty mounting brackets and bolts for easy installation.

Side column legs come with cylinder brackets that are pre-assembled, pre-welded and pre-hung at

the factory to secure each hydraulic cylinder.

Comes with pre-drilled mounting holes so through bolts can be easily attached to the building columns

to help secure the door assembly to the building structure.

Pre-locates the hinges for the doorframe.

Easy installation.

Pre-locates the upper hydraulic cylinder brackets.

Extra Strength.

Provides additional structural support.

Others may lead you to believe that because of the doors subframe . . .

Building does not have to be made stronger.

Building does not have to be modified to hold a door.

Building does not have to be engineered with extra reinforcement to accept a door.

Customer does not need to do anything to the building.

Door does not hang on your building.

Will you be attaching the doors subframe header to our building structure in any way or will it stand alone by it's self?

Will you be securing the vertical subframe side columns legs, that the cylinders are attached to, to the building structure or will they stand alone?

With all the myths listed above, it sounds like no one is relying

on the buildings structure for added support... I DOUBT IT!

The horizontal subframe header tube is bolted / connected to the building's structural header.

The cylinders are attached to the verticle subframe columns and bolted / connected to the

building's side columns.

The cylinders are attached to the moving door frame while being fixed to the subframe side

columns legs, which are directly bolted / connected to the building structure.

The subframe is an important part of delivering a pre-assembled

hydraulic door with the pre-located cylinder brackets and hinges for

ease of installation!

Telling your customers . . . "There is no need to do anything to the building

to accept a hydraulic door . . ." could be far from the truth or even unsafe!

The building manufacturer / contractor / owner is responsible

to ensure that the building's structural design is capable of

handling all the imposed loads that the door exerts to your

door header, end wall, and building.

Your building header/column design must meet standard

deflection and strength criteria, both in vertical and horizontal

directions to support the Hydraulic door in all positions.

Schweiss provides easy-to-read, necessary specs sheets with

each door showing all the forces and building header

requirements.